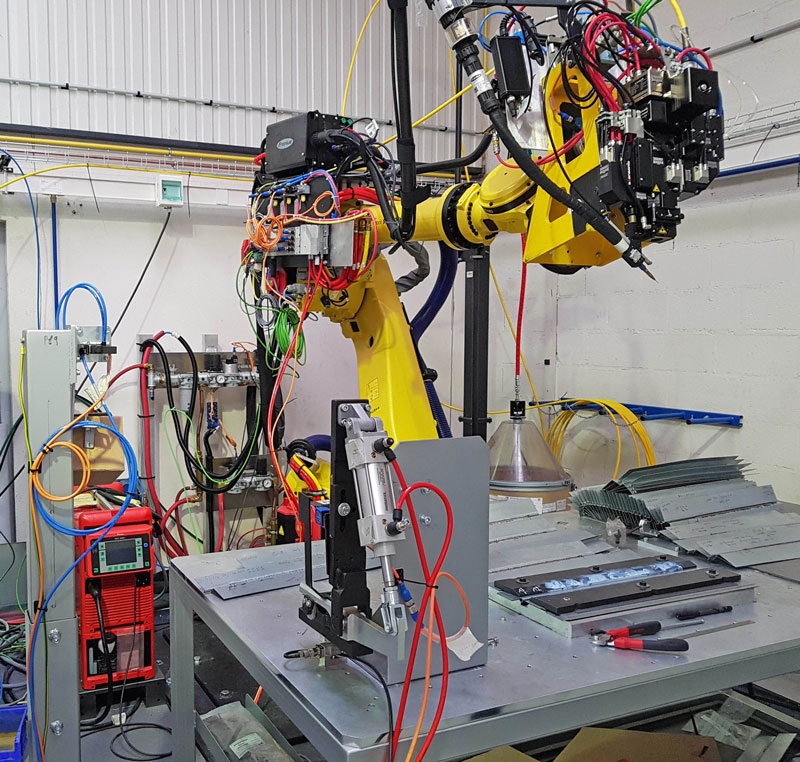

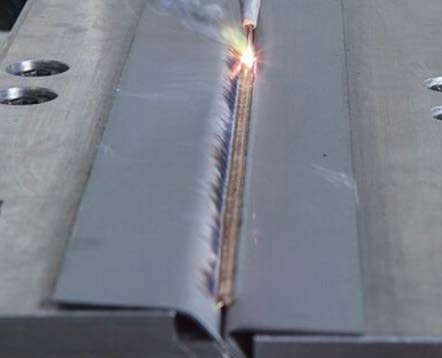

Robot with laser brazing

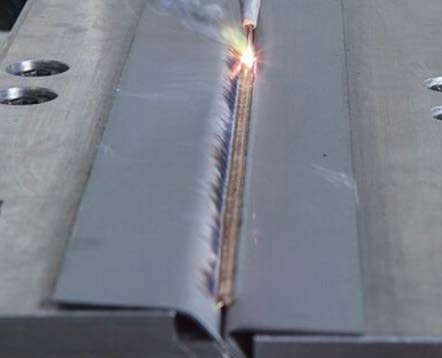

Laser brazing seam

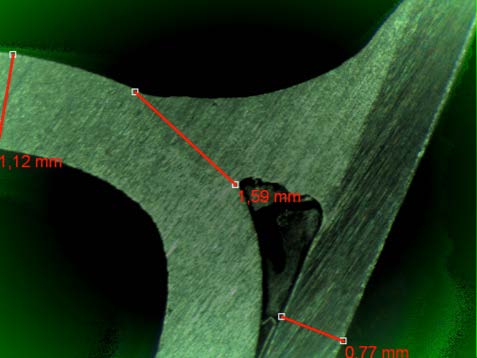

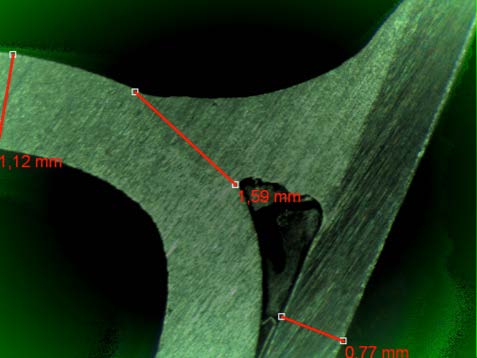

Metallographic cut of laser brazing

Laser brazing Laser brazing is a process of assembling identical or dissimilar materials by means of a supply of material. Laser brazing with wire feed allows the assembly of sheets by means of a wire feed that is melted in contact with the beam and the parts to be assembled. This type of laser brazing is mainly used in the automotive industry for the assembly of pavilions or certain parts of the body. Laser brazing can also be carried out with the addition of an intermediate interface (foil, paste, etc.) placed between the two parts to be assembled.

In the case of brazing by adding an intermediate interface (foil, paste, etc.), the optics used will integrate a homogenizer element in order to uniformly heat the area to be assembled.

Robot with laser brazing

Laser brazing seam

Metallographic cut of laser brazing

The diode laser is most often associated with a soldering optic which makes it possible to work on shaped surfaces. In this configuration, the optic is preferably mounted on a polyarticulated robot. The choice of wire is made according to the materials to be assembled (galvanized sheet, aluminum sheet, etc.). This laser process generates a smooth and very aesthetic brazing bead, thus limiting rework.

Wire-fed laser soldering achieves speeds of several meters per minute with laser sources of several kilowatts.

The oil company is also using laser brazing on an experimental basis with a supply of wire in successive layers to assemble very thick pipelines…