Principle of laser welding of thermoplastics

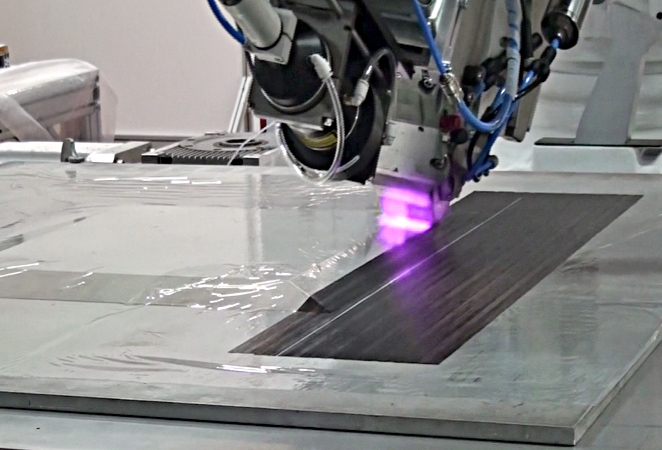

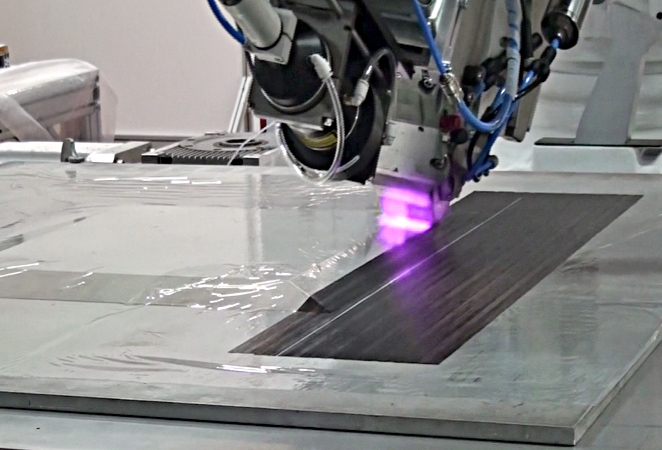

Principle of Laserline diode laser layup of carbon fiber parts

Stainless laser welding

Laserline diode laser pipe welding

Welding of copper with Laserline blue laser diode

Welding of copper with Laserline blue laser diode

Batterie welding done with Laserline blue laser diode

Composite laser welding production line

Soudure laser inox

Soudure laser pulse relais

Soudure laser soufflet

Soudure laser tête de clou

All materials that can be welded conventionally are laser weldable. The quality and speed of laser welding performed by laser machines is far superior to conventional processes and much more economical. Depending on the power of the laser source used, the welding will be carried out by thermal conduction for small thicknesses or by keyhole (steam capillary) for large thicknesses which require high laser power. It is also possible to weld thermoplastics and composite materials by laser. Diode laser sources are most often used with wavelengths suited to the materials to be welded.

High power welding uses a high intensity laser source (several kilowatts) that allows welding of large thicknesses or multiple thicknesses. This process creates a vapor capillary through the thickness of the material which is maintained throughout the welding process. Laser welding in keyhole mode achieves a welding speed of several meters per minute with high weld quality.

Le soudage par conduction thermique est utilisé sur des épaisseurs plus faibles (1 à 2 mm). Seule la surface est fondue. Le cordon de soudure est en général plus lisse et présente moins de porosités. Ce procédé de soudage est le plus souvent utilisé lorsque les cordons de soudure sont apparents et que l’aspect esthétique de la pièce est un critère important (éviers, soufflet métalliques…).

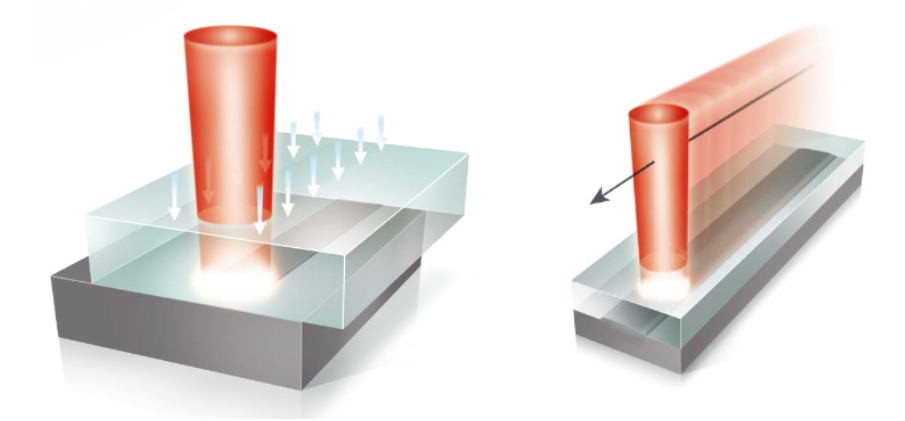

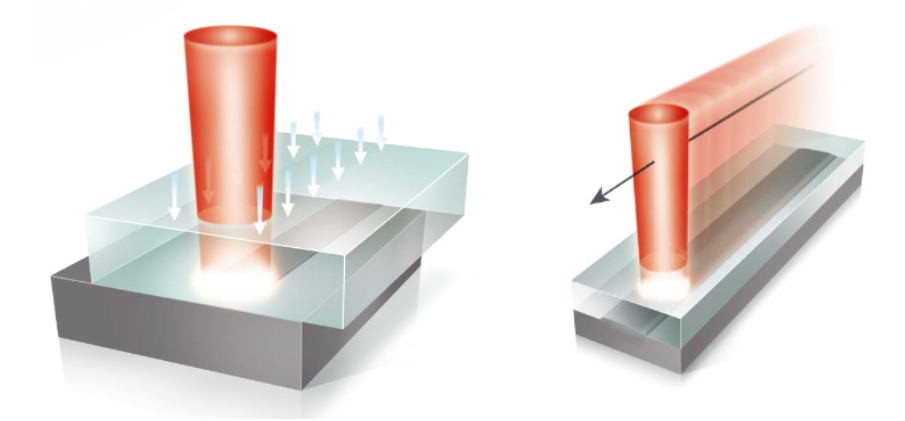

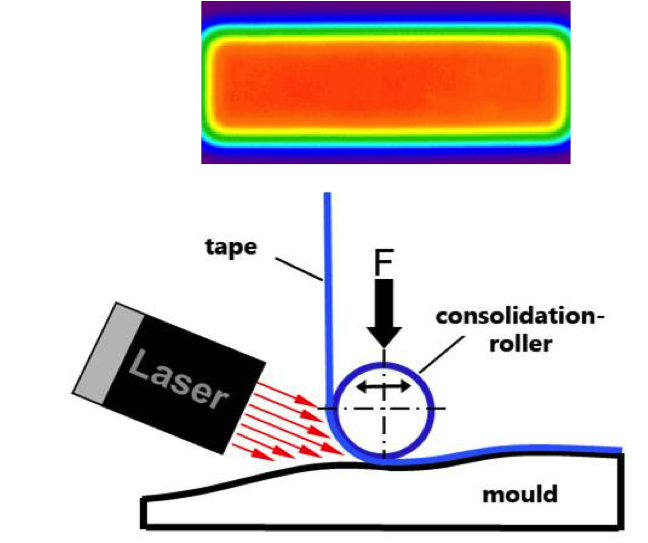

Principle of laser welding of thermoplastics.

The laser beam passes through the upper substrate which must be transparent to the laser wavelength, while the lower substrate is absorbent. The latter by thermal conduction will melt the upper substrate. During welding, the two parts to be assembled are subjected to mechanical pressure which keeps them in contact until the end of the process. The two substrates are thus welded by laser.

Principle of laser welding of thermoplastics

Many systems equip the automotive industry for the welding of many parts integrated in today's vehicles: pump, sensor, electronics, keys, headlights and also certain body parts…

The medical field is also a major user LPKF systems for the welding of numerous parts: various tubes, capsules, filters…

That laser welding of thermoplastics is a clean process, without chemical waste (no glue, no solvents), and without mechanical contact since it is the laser beam that melts the plastic and thus welds the parts together.

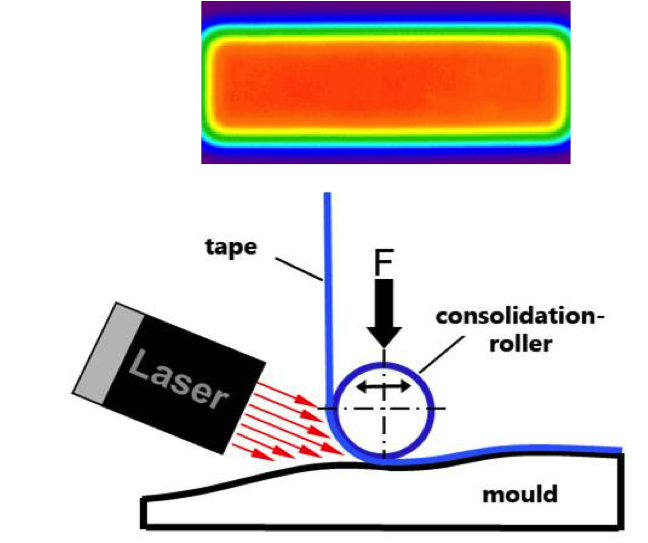

Principle of Laserline diode laser layup of carbon fiber parts

Principe du drapage par laser à diode Laserline de pièces en fibre de carbone